- Россия, г. Кострома

- +7(920)399-93-61

- office@granteez.com

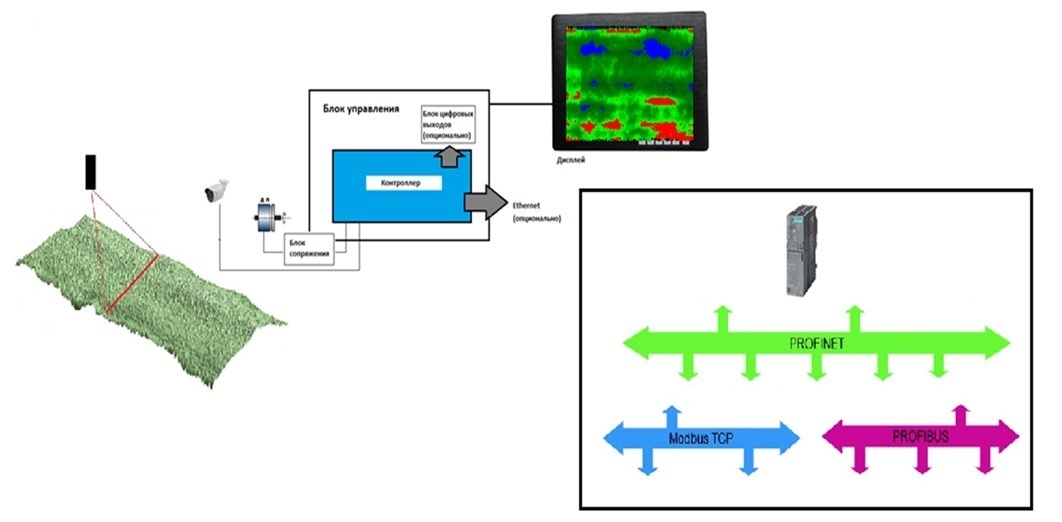

SURFACE scanner

The scanner of the chipboard forming machine is the ideal solution to the problem of uneven filling, which leads to thickness variation, different density of the finished plate and, as a result, to a decrease in the quality of the finished product. The scanner allows you to monitor and analyze the height and irregularities of the carpet (hillocks and pits) in real time, which allows operators to take timely measures to eliminate the production of poor-quality products. Thus, the scanner is a tool for intermediate control of the manufactured plate, allowing you to achieve high quality, reduce production costs and waste losses..

• Scanning the surface, after the forming machine

• Flexible adjustment of adjustable parameters for each layer thickness

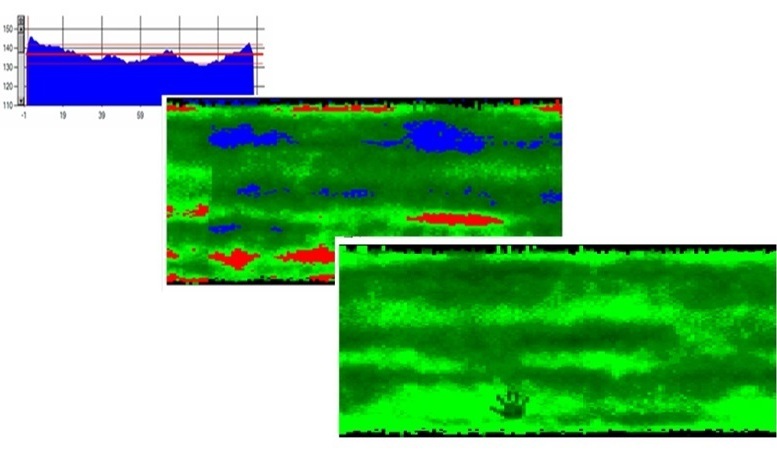

• Visual representation of scan results

• Transmission of control signals to the process control system

• Save scan results to the database

• Reducing material and energy costs

• Optimized material utilization due to longitudinal and transverse profile analysis

• Connection to an automatic process control system

• Non-contact scanning of the surface of the material, after the forming machine, across the entire width

•High accuracy

• Control block

• Scanner module

• Distance sensor

• Motion sensor interface unit with controller

• Industrial panel monitor

• Operator's PC + panel monitor (optional)

• Communication with process control system (Profinet, Profibus, Modbus) (optional)

• Block of digital outputs for generating external binary signals (optional)

• Thickness measurement range 0 ... 180 (400) mm

• Measurement accuracy ± 1 mm

• Scan frequency 30 Hz

• Supply voltage ~ 220 V, 50 Hz

• Temperature 0 ... + 45 С